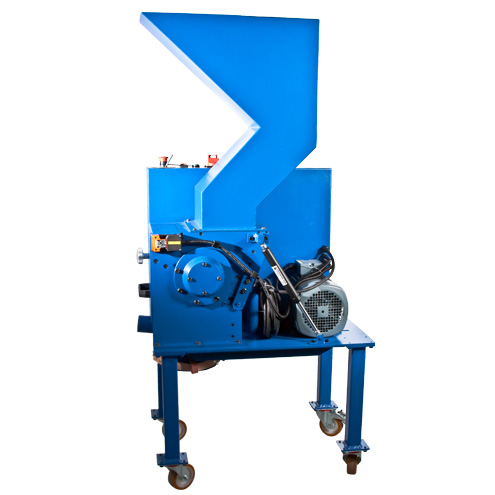

CM1000 Cutting Mill

The CM1000 Cutting Mill is used to grind solid materials such as rubber, plastic, wood, foils and many other materials.

The processing material falls into the cutting chamber via a guide chute and is shredded by cutting between rotating and fixed knives until it passes an attached sieve as ground product. The sieve extends over the lower half of the grinding chamber and can be changed easily. Final particle size is determined by the selected sieve perforation aperture.

When the grinding process is finished the grinding chamber is fully accessible by unscrewing two hand screws and folding back the feeding hopper. The grinding chamber is fully accessible for quick and easy cleaning.

- Rapid reduction of large particles

- Quick and easy to clean

- Rapid sieve and knife changeover

- The CM1000 can handle samples of up to 60Kg/h

High operator convenience and maximum safety

The CM1000 Cutting Mill is the first machine in a state of the art sample preparation laboratory when it comes to sample preparation of cuttable materials. This system is suitable for the coarse and fine grinding of any dry substance, typically samples with a feed size of up to 100mm and a total batch of up to 60kgs per hour (volume depending on the characteristic of the samples) can be ground down to 0,5 mm or finer depending on the product.

Maximum Grinding performance and maximum safety is important for LAARMANN Mills. Due to the integrated safety switch the machine can only be started when the “Easy Lock Cover“ is closed and the grinding chamber cover is inserted properly. The Infeed Hopper as well as the housing of the CM1000 is made from solid steel. The ergonomic design of the machine and the positioning of the funnel and the starter box require a minimum space in the laboratory.