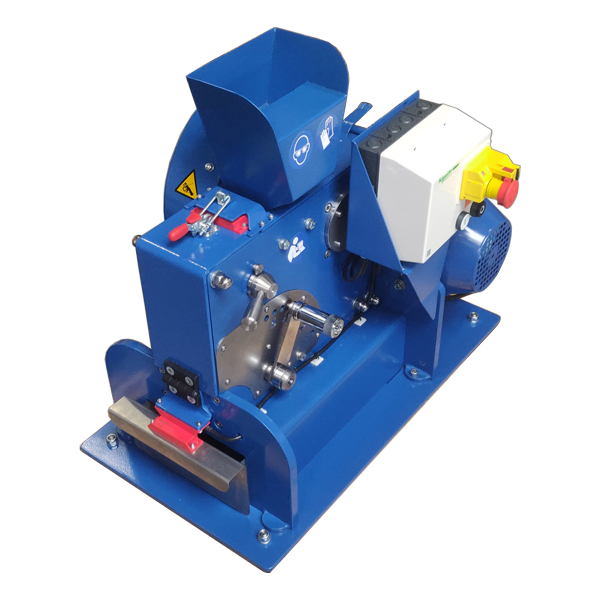

LMC50 Jaw Crusher

LMC50 features in the compact design, easy operation and the high final fineness of sample (d90 < 0.5 mm).

- Final fineness (d90 0.5 mm)

- Zero point adjustment

- Six kinds of materials for the jaw plates to choose from

- Easy cleaning

- Anti-splashing hopper

The sample enters the grinding chamber via the anti-splashing hopper. The crushing is proceeded inside the wedge-shaped shaft space between two jaw plates. one jaw plate is fixed, while the other jaw plate is driven by a bent axle to perform oval movement with the continuous rotation of the motor.

The sample is crushed due to extrusion caused by constant movements of the jaw plate and moves downward under the effect of gravity. In case the grain size of the sample is less than the lower opening gap of jaw plates, it will fall to the drawer receiver at the lower part of the machine.