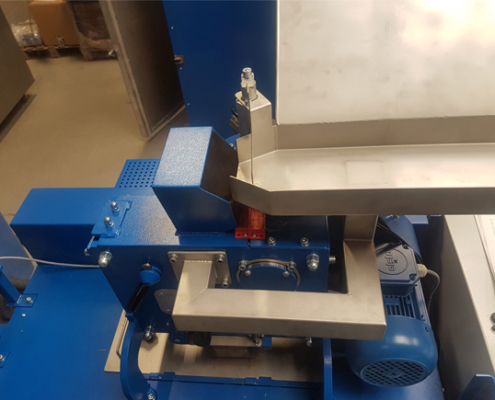

LMCOM Combi Mill

The LAARMANN LMCOM Combi Mill is a laboratory sampling machine that combines a small jaw crusher and rolls crusher with a sampling element. The sample is placed at the top and transferred into the jaw crusher. After the sample is processed, the sample falls into the rolls crusher to make the end fineness smaller. When the sample is processed by the rolls crusher, the sample falls on a small sieving street that transports the sample with a vibratory feeder. In this particular application, the required end fineness falls into a small bottle and the larger sample materials falls into the reject sample collector. The bottle can be easily taken out with a large handle. When this is done, the vibratory feeder stops so that no sample is lost. Our LMCOM Combi Mill can be used to process different types of material with just one machine.

The jaw crusher:

a fixed jaw plate adjacent to a moving jaw plate, in a V configuration, narrowing to an adjustable gap between the bottom edges of the two plates. The moving plate oscillates back and forth, driven by an eccentric pitman shaft, powered by V belts from a standard electric motor.

The sample material is fed into the large top opening of the jaw plates via a vibratory feeder and is crushed by the oscillating jaw plate as it passes through the narrow gap at the bottom, into the rolls crusher.

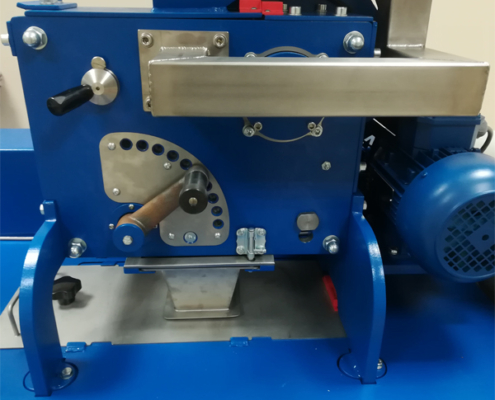

The rolls crusher:

The gap between the individually, direct drive, rolls can be adjusted to increase or decrease the outcome particle size. Throughput of the machine will move in the opposite direction. By adding the product on the top side of the machine the rolls will crush these down to the desired size by rotating towards each other. At the bottom of the machine the output will enter a vibratory feeder with an integrated sieve. The small particles will enter the collecting pot and the larger particles will follow through towards the reject.

The sample collector

The vibratory feeder transports the sample over the sieving street. The sieves can have different kinds of sizes. This depends on the sample material that is being processed. The swing uses weights to stay in place and with the swing the sample is taken out. The swing is equipped with a sensor that detects when the swing is not in position and will stop the vibratory feeder when it’s being lifted.