LAARMANN Biomass sampling installation

Biomass sampling installations

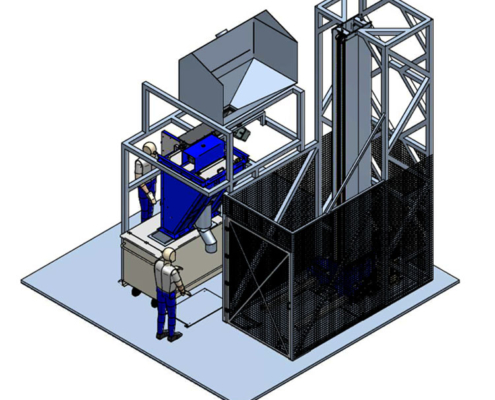

LAARMANN has designed and developed two installations for biomass processing. The first installation is used for lifting bins with biomass sample material that are then divided with a Vezin Sampler and after that with a RSD Rotary Sample Divider into 6 buckets with 10L volume.

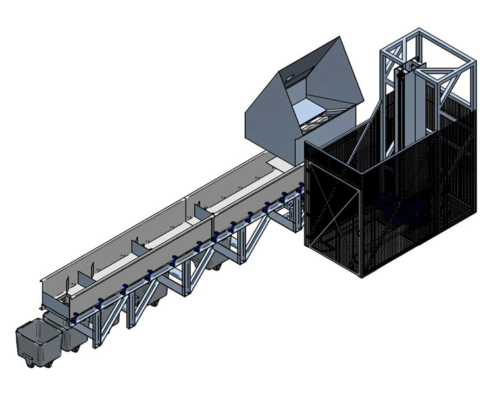

The second installation is used for Particle Size Distribution of biomass. It has a lifting device that lifts the container with biomass material that will then will be distributed with a sieving street.

Our client processes their biomass material in a shredder and it requires our sampling installation to get a representative sample. Our other installation is used to check if their biomass material is modified and for size distribution.

Biomass Sampling Installation: How it works

The installation has a digital control panel with a user-friendly interface that is convenient to use for the operators. It’s possible to change parameters such as:

- the percentage of the vibratory feeder

- the rotating speed of the vezin sampler

- delay of the sampling spoon

Advantages:

- Container with a laser detection for dosing

- Representative sample because of the Vezin Sampler and RSD Rotary Sample Divider combination

- Outlet feeder connected by a flexible connection to a VS200 Vezin Sampler

- Sample will be rejected in a RSD60L rotary sample divider

- Reject material collected in a big bag

- 60L sample is collected with the RSD60L Rotary Sample Divider that has different size combination of buckets

Particle Size Distribution installation: how it works

The sample is lifted up in a large bin with a lifting device the bin will tilt so that the the sample will fall onto a sieving street. The vibrating sieving street has different sizes of screens to distribute the sample. The ideal height of the vibrating screen from the PSD (Particle Size Distribution) will be between 1,1 and 1,6 meters, where the goal must be that if possible, the Operator can stay on the ground while looking into the vibratory feeder of the PSD.

Features and advantages:

- Sieve grid in the intake hopper which is adjustable in width

- Has round bars inside so no product stays on top

- Basic 200 to 350mm adjustable by slide in blocks sieve grid

- Screens are interchangeable if fuel specifications change

- Current screens: 3.15mm, 8.00mm, 100.00mm, 200.00mm

The installation has a digital control panel with a user-friendly interface that is convenient to use for the operators. It’s possible to change parameters such as:

- The lifting speed of the bin, The container will automatically tilt when the tilting point has been reached.

- The sieving street also has changeable parameters such as the frequency of the vibratory sieve and the delay in seconds before the sieve speeds up to the second and third frequency before returning to the first frequency.

LAARMANN particle size distribution installation