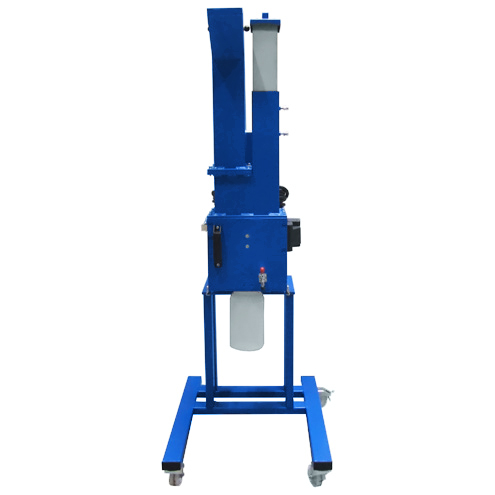

CM500 Cutting Mill

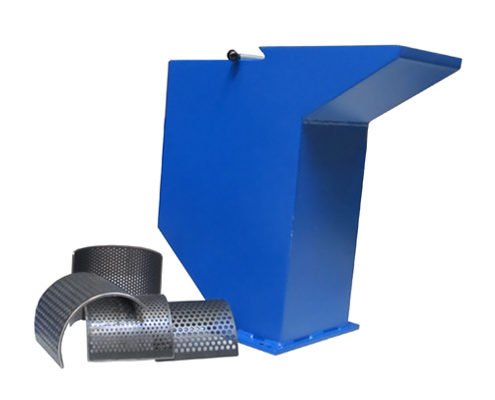

The CM500 Cutting Mill is used for batch and continuous grinding of hard, soft to brittle and tenacious plastics among many other products like, rubber, wood, grass, herbs etc. It is possible to choose between different feed hoppers and different knifes from hardened steel, tungsten carbide or heavy metal-free-steel depending on the grinding material. At the end of each milling the door can be opened to remove the knifes and easily clean the grinding chamber.

- Rapid reduction of large particles

- Quick and easy to clean

- Full range of bottom sieves

- Interchangeable knives

- The CM500 can handle samples of up to 30Kg/h

High operator convenience and maximum safety

The Cutting Mill is the first machine in a sample preparation laboratory of today when it comes to sample preparation of cuttable materials. This system is suitable for the coarse and fine grinding of any dry substance, typically samples with a feed size of up to 100mm and a total batch of up to 30kgs per hour (volume depending on the characteristic of the samples) can be ground down to 1,00 mm or finer depending on the product.

Maximum Grinding performance and maximum safety is important for LAARMANN Mills. Due to two integrated safety switches (door and collector) the machine can only be started when the “Easy Lock Cover“ is closed and the Sample collector is inserted properly. The Infeed Hopper as well as the housing of the CM500 is made from solid steel. The ergonomic design of the machine and the positioning of the funnel and the starter box require a minimum space in the laboratory.