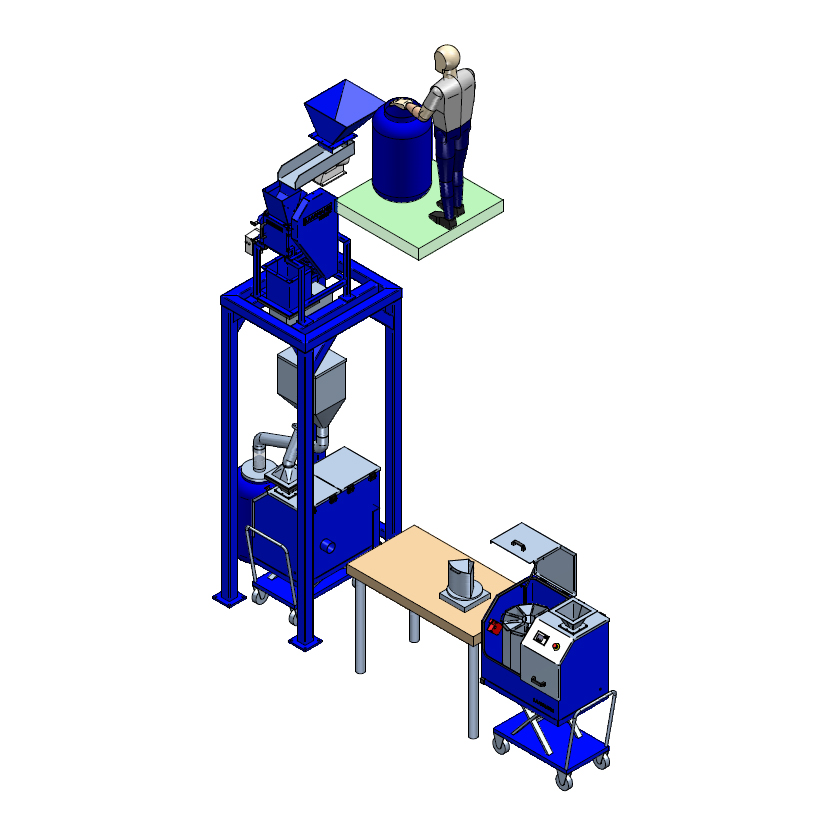

Installation with LMC200D and Rotary sample divider

The vibratory feeder fills the LMC100D (jaw crusher) and another vibratory feeder underneath creates a homogeneous free falling stream of fines. From this stream a material sample is taken and the rest of the material is released into a Rotory Sample Divider (RSD). This RSD has different buckets which are produced with different angles. The rejects are are dumped in a 200L barrel, this way the customer is able to take a sample in one go. After this bag sampling process the operators puts around 100kg of Ferro ore (FeO) trough.

.