Order for large mining/recycling company in Africa

The order consists out of:

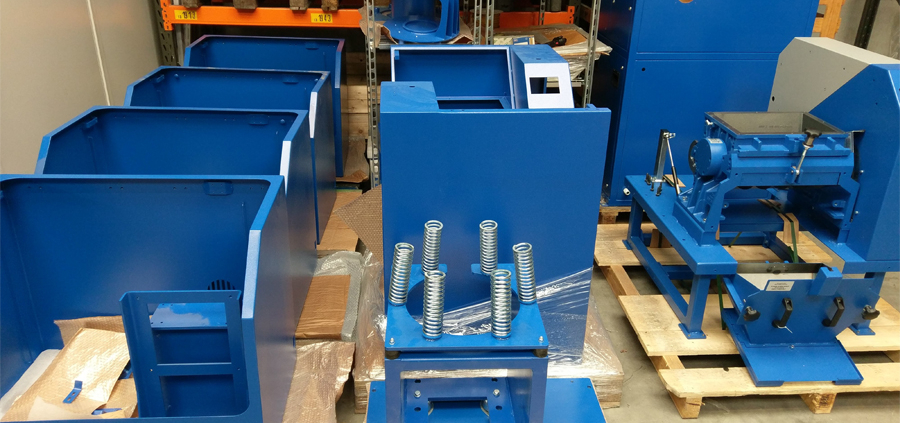

4 x Rotary Sample Divider 60 Litre (RSD-60L)

The RSD-60L can be used to divide a maximum of 60litre in 1 or more sub-samples. At this stage of the production the housing came back from the paint shop. The rotating table, control box and lids are being produced while the customer determines which bucket set combination is required.

The bucket set will be drawn (if needed) and produced two weeks before final assembly to give the customer all the time needed to determine the best suitable combination of buckets.

1 x CM4000 cutting mill.

The CM4000 is our largest cutting mill. This mill is suitable for a feed size of 250 mm x 385 mm and will reduce this down to <1.0mm at a flow rate of 20 – 200kg/h depending on the material. This particular cutting mill will be used in a research for recycling of precious metals.

2 x LM1000 pulverizing Ring Mill

The LM1000 is suitable for grinding media up to 1000cc. This grinding media consist out of a bowl, puck and lid or with smaller volumes out of a bowl, inner ring, outer ring and lid. For this particular order we are producing 3 x 100ml tungsten carbide light grinding media and 2 x 1000cc chrome steel grinding set.

1 x LM2000 pulverizing Ring mill

The LM2000 is suitable for grinding media up to 2000cc. The grinding set needed will be 2000cc chrome steel. The LM2000 will be used to mill materials like FeCr, FeTi and other ferro alloys.

Laarmann Group B.V.

Laarmann Group B.V.