View of Laarmann warehouse

CM1000 Cutting Mill

LMBRM Ball and Rod Mill

LMFC250 Fine Crusher

LMC100D Jaw Crusher

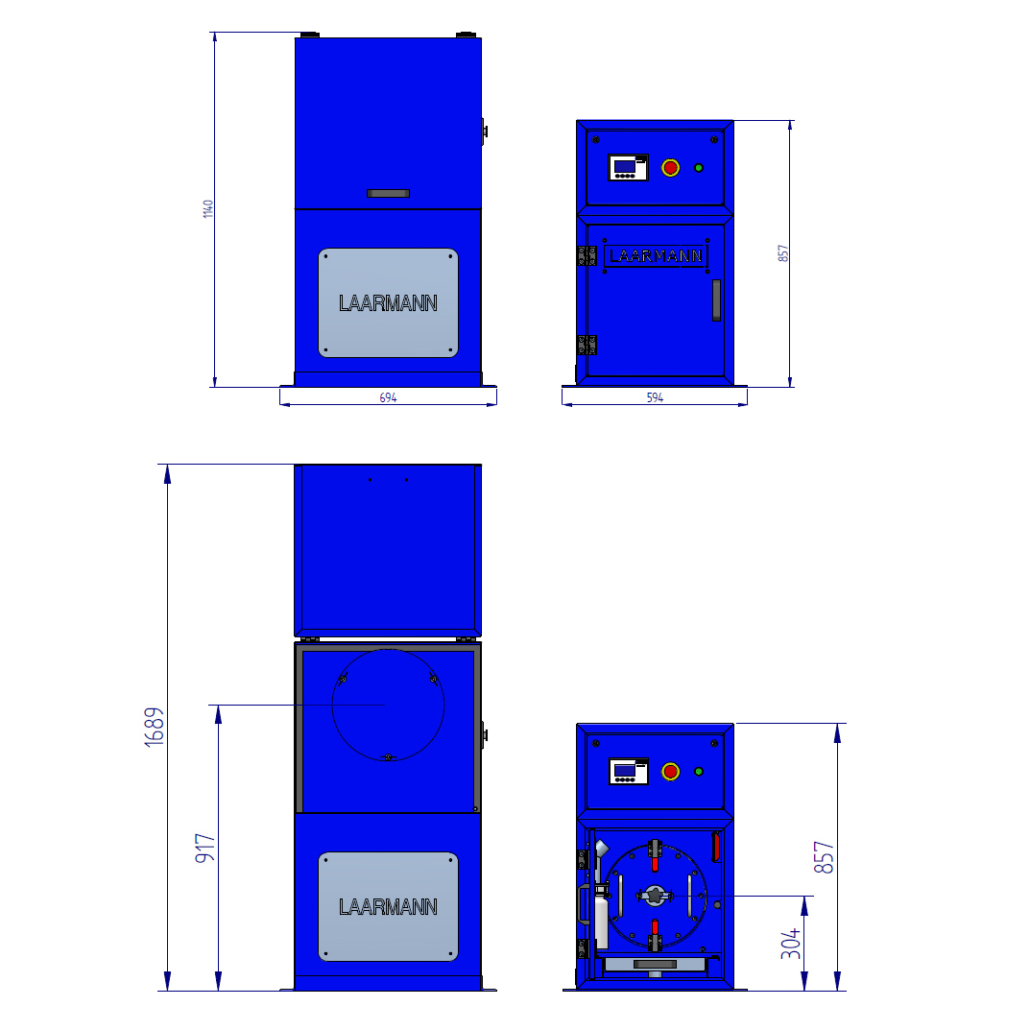

The Bond Abrasion Tester is a process and laboratory machine, which is designed to determine the abrasion index of a mineral sample to be determined in accordance with F.C. Bond´s abrasion test method. The newest version is now even more compact and reliable.

Left is the old version which is driven by a chain and right is the new version driven by a v-belt.

The popularity of the Laarmann Flotation machines has risen in high numbers. Recently large amount of orders that consist of flotation machines and flotation cells has been received

The orders consist of:

7 x LMFTM Flotation Test Machine

The versatile Laboratory Flotation Bench has been designed to provide an accurate reliable means of reproducing test results. The newest version makes use of a touch screen to control it and magnets to connect the rotors

30 x Flotation Machine Cell

The flotation cell for the LMFTM Flotation test machine is made from clear arcylic with polyurethane impellers. The throughput capabilities of various cell designs will vary with the flotation machine’s residence time and pulp density

The LAARMANN Sampling installation is a multi-ton system designed to take a representative sample from a large stream while filling big bags for later processing.

Laarmann has successfully finished production of the Continuous Ball Mill.

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the grinding balls drop from near the top of the shell.

The Continue Ball Mill is divided in three main components:

Vibratory feeder

A vibratory feeder on a lift to feed the ball mill. The vibrating speed is adjustable.

Continuous ball mill

The ball mill’s position can be tilted to control the flow for both wet and dry grinding. The doors are also removable for easy access and cleaning.

Collecting hopper

For catching and pumping the material. Works with an air operated dia frag pump.

Laarmann has began to develop their own Fire Assay, Fire assaying is used to recover metals by the fusing of the materials at high temperatures for example gold witch usually go up to 2000 Degrees F. Fire Assay is a very old method but still the most reliable

The setup consist of:

- Rotary Sample Divider

- LMC200D Jaw Crusher

- LMBR2000 Bottle Roller

- Hot pot trolley and work station

- Pouring trolley

- Tool rack with rake, fork, shovel, brush and tong

- Pot rack with crucibles

- Knockup bench

- Grid bench

- Cooling rack

- Crucibles

- Cupels

Laarmann has finished production of a large order and is ready for shipment

The order consists of:

1 x Flotation test Machine

2 x LMC200D Jaw crusher

1 x LMRC100 Roll Crusher

1 x LMBM Ball Rod Mill

At Laarmann we are always looking to improve our Machines. A great example is our new Impact Tester. It originally needed to be operated manually by multiple people using a pulled rope. This caused the results to be different depending on who was pulling. Our team of engineers came up with a design using two magnets that can be released with the push of a button.

A lot of advantages came with the new design:

• The angle can be set with a pin making the results repeatable

• Setting the angle is always and everywhere the same

• Non hazardous operation by pressing two buttons simultaneously

In the video down below you can see a demonstration of the machine in action.

The order consists out of:

4 x Rotary Sample Divider 60 Litre (RSD-60L)

The RSD-60L can be used to divide a maximum of 60litre in 1 or more sub-samples. At this stage of the production the housing came back from the paint shop. The rotating table, control box and lids are being produced while the customer determines which bucket set combination is required.

The bucket set will be drawn (if needed) and produced two weeks before final assembly to give the customer all the time needed to determine the best suitable combination of buckets.

1 x CM4000 cutting mill.

The CM4000 is our largest cutting mill. This mill is suitable for a feed size of 250 mm x 385 mm and will reduce this down to <1.0mm at a flow rate of 20 – 200kg/h depending on the material. This particular cutting mill will be used in a research for recycling of precious metals.

2 x LM1000 pulverizing Ring Mill

The LM1000 is suitable for grinding media up to 1000cc. This grinding media consist out of a bowl, puck and lid or with smaller volumes out of a bowl, inner ring, outer ring and lid. For this particular order we are producing 3 x 100ml tungsten carbide light grinding media and 2 x 1000cc chrome steel grinding set.

1 x LM2000 pulverizing Ring mill

The LM2000 is suitable for grinding media up to 2000cc. The grinding set needed will be 2000cc chrome steel. The LM2000 will be used to mill materials like FeCr, FeTi and other ferro alloys.

The order consists out of:

3 x LMBR500, LAARMANN bottle roller 500.

The LMBR500 is a very convenient table top bottle roller which can be used with bottle up to 5 litre. The axles can be adjusted to fit one or more bottles from different diameters depending on the exact requirements. The bottle which is used can be equipped with grinding balls for milling.

1 x LMAJ200, LAARMANN Air Jet Sieving Machine 200.

The LMAJ200 will be used to determine the particle size distribution for real fine particles. For this particular order mesh sizes within the range of 100µm – 150µm, we can deliver sieves from the range of 20µm up to 4000µm. The vacuum unit can optionally be purchased when needed.

1 x Rotary Sample Divider 60 Litre (RSD-60L)

A 60 litre batch needed to be divided into 6 portions. In this particular case the portion are an equal 10litre sample. When needed the collecting buckets can be adapted to the requested volumes. 3 x 10 litre and 6 x 5litre for example.

The customer requested a low infeed hopper and the machine needed to be moveable in order to bring the several sub-sample to different area’s of the laboratory.

1 x Rotary Sample Divider – reject 10Liter (RSD-R 10L)

The customer requested a smaller rotary sample divider dedicated for a specific product. This machine will be exclusively be used for dividing a ±10litre sample into 4 x 1 litre. The remaining sample will be collected underneath the machine through the reject passage.